Introduction

Vibstop isolation material is a specifically designed vibration absorbing medium. Produced as a cost effective solution to foundation isolation.

In positioning a machine tool a degree of planning is required. Is the machine tool likely to create vibration which may affect neighbouring plant or equipment? Is the machine tool high precision, will it be affected by ambient vibration? It may, in some circumstances be prudent to have a vibration survey carried out for the proposed site to establish exact data prior to work commencing.

Designed with ease of installation in mind, Vibstop is an excellent medium for controlling high frequency vibration and impact shock inputs to or from machine foundations.

Many “full coverage” vibration isolation systems suffer from reduced vibration efficiency over time due to water absorption and creep. This results in the resilience of the isolator being affected, as Vibstop is a closed cell elastomer it is unaffected by moisture ingress. The long term performance of Vibstop can be described as constant over time.

Designed to be installed for the lifetime of the machine foundation Vibstop is resistant to most work place chemicals and performs consistently over a wide temperature range.

Produced in standard panel sizes for base and wall isolation, available in three different thickness. To make the installation more cost effective different thickness’ of Vibstop can be used on the base compared to the walls.

Installation

There are two recognised methods to install Vibstop.

Option One

- Floor slab is cut and pit excavated.

- Base and walls constructed.

- Base and walls are covered with Vibstop.

- Foundation block is cast.

Option Two

- Site is excavated to required depth.

- Vibstop is installed directly onto open ground.

- Shuttering positioned and block cast.

- Shuttering striped.

- Vibstop fixed to the block sides with silicone adhesive supplied.

- Soil is back filed up to the Vibstop.

- Floor slab is cast on finished grade

Technical Specifications in detail

Vibstop is a closed cell medium density material. It has been specifically designed to give reliable vibration isolation performance. It is unaffected by most work place solvents and oils and is largely unaffected by ambient temperature. It has been specifically designed to resist “creep” giving excellent long term performance.

Composition

- Supplied in standard sheet sizes of 108″ (2750mm) by 24″ (600 mm)

- Range of thickness 1/2″ (12.5 mm) 1″ (25.4 mm) and 2″ (50 mm)

- Two available grades are available. M (medium) up to 5 psi, (3.5 Kg/sq cm) and H (high) up to 10psi, (7 Kg/sq cm)

- High resistance to common oils and solvents.

- Prolongs the life of machinery.

- Retains its properties for good service life.

- Installation

- There are two recognised methods to install Vibstop.

- Option One

- Floor slab is cut and pit excavated.

- Base and walls constructed.

- Base and walls are covered with Vibstop.

- Foundation block is cast.

- Option Two

- Site is excavated to required depth.

- Vibstop is installed directly onto open ground.

- Shuttering positioned and block cast.

- Shuttering striped.

- Vibstop fixed to the block sides with silicone adhesive supplied.

- Soil is back filed up to the Vibstop.

- Floor slab is cast on finished grade

Conclusion:

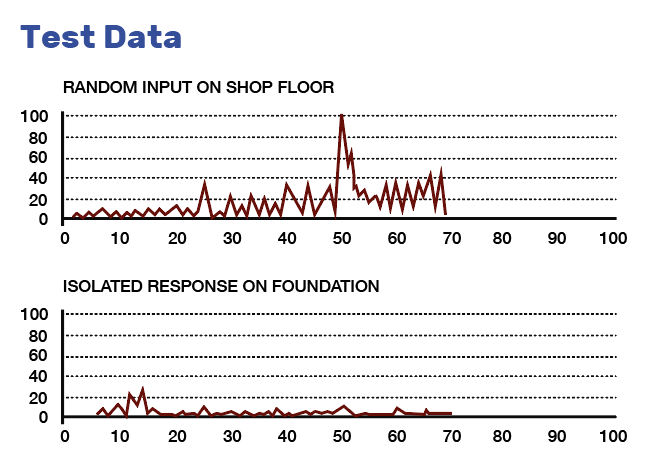

As can been seen above the Random Shock input on the shop floor excites the floor to “ring” at a range of frequency peaks. These are likely to disrupt machine operation, repeatability and surface finish.

Simultaneously looking at the response on the Isolated Foundation while experiencing the same shock input demonstrates the effective protection VIBSTOP offers against the input.

NOTE: Prior to recommendation of a product Armadillo VSC may need to take site measurements. Please call for details.

Once a suitable size foundation mass is calculated the ground is excavated to make room for the form work. After casting the base of the pit form work is constructed for the pit walls. These can also be produced from block work. Reinforcing bar may be incorporated into the design.

Once the pit walls are completed the VIBSTOP can be installed.

As VIBSTOP is designed to be a full area coverage material there is no need to use shuttering above the isolation material. Once the base and walls are covered concrete can be directly cast. Adhesive is supplied with the system to bond the isolation panels to the pit walls.

As can be seen here it may be necessary to install additional reinforcing bar for the foundation block. Armadillo VSC can advise.

Box outs may be added to the top surface of the block to accommodate levellers or anchor bolts. (Ask Armadillo for details on these products.)

The top surface of the block can be cast flush with surrounding floor as there is little differential settlement once the machine is installed.

The finished article. Installation of the machine now takes place. As can be seen pockets have been cast into the surface of this block to accommodate the grouting in of foundation bolts. Armadillo VSC can advise and supply epoxy foundation grout for this purpose.

Frequent terms used to discribe Vibstop foundation applications are, insolated intertia base, isolated foundation, building isolation, antivibration cork foundation, tico foundation, isolated foundation block.