Introduction

In many heavy engineering applications large inertia and impact forces can be generated which if left unchecked can cause numerous problems. These can range from simple noise nuisance right up to destruction of the equipment and foundation. These need to be accommodated to prevent damage being caused to the foundations or surrounding equipment.

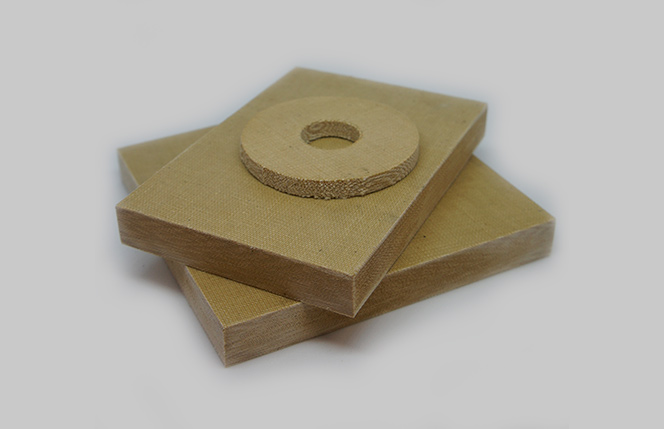

Armadillo Nitrile is a scientifically designed elastomeric pad specifically for this purpose. Originally developed to absorb shock loads under forge hammer anvils, Armadillo Nitrile is now also used as a heavy-duty mounting pad for reducing vibration from large plant and as a general duty shock absorber Combining high stiffness with great durability and resistance to impact. Ease of custom-moulding makes it ideal for many special applications.

Composition

Armadillo Nitrile consists of a closely woven fabric gauze which has been impregnated with a nitrile elastomer. Multiple layers are pressed together while under tension then vulcanised to form a highly resilient pad possessing exceptional compressive strength and unrivalled damping properties.

- There is no “shape Factor” involved with Armadillo Nitrile.

- Exceptionally high internal damping (C/Cc -.14)

- Long term creep is less than 5% of the original thickness.

- Unusually high compressive strength – 12,000 psi (4185Kg / cms)

- High resistance to common oils and solvents.

- Un affected by steam, water, mildew and salt water.

- Readily bonds into multiple layers for a range of thickness’.

- Can be made into bespoke sizes and shapes.

- Prolongs the life of machinery.

- Retains its properties under extreme conditions.

Some practical aspects and considerations when using Armadillo pads

- Due to high stiffness offers good degree of stability and limited motion.

- Connections to isolated system should be made with flexible linkages to avoid fracture.

- Avoid metal-to-metal contact in mount attachments by including Armadillo Bushings and Washers.

Impact Shock Reduction

By incorporating some element of resilience into a system the effects of high energy impacts can be dissipated over a longer time period. This results in the maximum force transmitted into the system being reduced.

The pad area can be designed to limit the ultimate working stress of the pad while the thickness of the pad can be built up to increase the amount of deflection on impact. These two factors make Armadillo Nitrile the ideal choice in solving high impact problems.

Common Applications

- Forging hammer buffer pads.

- Resilient pads for roller table bearing chocks.

- End stop buffers in steelworks.

- Buffers for mine cages.

- Mounting high-load machines on irregular surfaces.

- Anvil pads on new and existing forging hammer installations.

- Anti-vibration mounts on large plant.

- Heavy duty buffers.

- Foundation protection for roughing mills.

High quality manufacturing process

Working Temperature.

Continuous temperature exposure limits for long life are 95°C maximum and – 55°C minimum.

Armadillo Material Tolerances:

Pad Length / Width 1.6mm

Pad Thickness (avg.) 5%

Strength and Compression

The ultimate break down of Armadillo Nitrile is in excess of over 1000 Kg per square cm before breakdown, this will vary with the thickness and plan area of the pad. In general compressive stresses should not exceed 140 Kg per square cms to attain a reasonable working life. Higher loadings can be accommodated please contact us directly for details.

Compression

As Armadillo Nitrile is manufactured from a woven fabric the material is compressible and does not rely on the elastomer to flow to be able to compress. Hence the deflection is not affected by the shape factor. On extremes of impact the overall dimensions of the cushion do not drastically change.

Set and Creep

Armadillo has been specifically designed to accommodate high loads while being able to resist the effects of long term creep. Over a period of time the total set is limited to be less than 5% of the original pad thickness. This has the enormous advantage of maintaining vibration isolation performance over time.

Density

1185 kg/m3

Compressive Modulus

As Armadillo Nitrile is an elastomeric material the load deflection curve is non-linear, therefore its modulus varies with load and is determined by:

M=1.5 X (stress/strain)

It approaches a maximum of 158 MPa at loads up to 13.8 MPa.

Static Spring Rate

As with compressive modulus, the static spring rate varies with loading. The formula is:

K = M X (Af/Tf) or K = 1.5 X (Force/Deflection)

Damping

As previously mentioned Armadillo Nitrile has a high damping value (damping constant 0.14). Its ratio of successive amplitudes (2 to 1) is about 4 times that of natural rubber and 100 times that of steel. The log decrement is 0.69. the high damping is because of the large energy loss per cycle (Hysteresis) this is between 25 to 45%.

Hardness and Stability

The Shore A Durometer hardness of Armadillo Nitrile is 90 ± 5. With the fabric reinforcement there is limited compressive movement giving a high degree of stability in the isolator.

Service Life

The unusual strength of Armadillo Nitrile and the fact it is a nitrile material give it excellent resistance to common oils, solvents and hostile environments means the service life will be far in excess of other pure elastomeric isolators.

Fabrication

Armadillo Nitrile is stocked in the form of pads, washers, bushings, and specially fabricated and moulded shapes in accordance with customers specifications and drawings. Special applications may require the addition of steel components.

Coefficient of Friction

0.6 fabric surface to bright mild steel

0.7 Armadillo surface to bright mild steel

0.8 Armadillo surface to concrete

Temperature Range

-40C* to +80C *

Recovery Properties

A pad 150 mm square 25 mm thick was compressed to 90% of original thickness under a static load of 15.5MN/m2 and on release exhibited these recovery characteristics.

99.2% Immediately

99.6% 1 Minute

99.7% 3 Minutes

99.8% 5 Minutes

99.9% 30 Minutes

Some Typical Pad Applications Include

- Bridges

- Buildings

- Cranes

- Fans/Blowers

- Forging Hammers

- Foundry

- Heavy Industrial Machinery

- Marine

- Military

- Mining

- Pipelines

- Presses

- Printing Presses

- Pulp & Paper Equipment

- Steel Chimney Damper

- Scales

- Railroad and Transit

- Steel Industry