Introduction

Armacork is a direct equivalent to Tico S antivibration cork.

The vibration control properties of rubber bonded cork have long been recognised in machine installations. By combining the resilience of the cork with a nitrile elastomeric compound a product has been produced which gives excellent vibration isolation characteristics with the benefit of long term protection against creep and set.

Offered in various sheet sizes and thicknesses Armacork is the ideal entry level material to offer a cost effective and fast vibration control solution for many industrial applications.

The introduction of Armacork between the machine base and the supporting foundation effectively prevents the transmission of structure borne disturbance to the adjacent areas. Supplied in sheet form allows the installation engineers to tailor the pad area to suit the load conditions.

In many applications the degree of isolation can be increased by simply mounting multiple layers of Armacork to form a thicker isolation pad.

Composition

Armadillo Armacork is manufactured with natural cork granules blended with a medium duty neoprene elastomer. This ensures the natural resilience of the cork particles can resist attack from oils, solvents and common place factory acids.

Further more the Armacork has been designed to give a long service life and has excellent resistance to long term creep and set. This means the pad substantially retains the original isolation performance over time.

- Supplied in standard sheet sizes for on site cutting or can be supplied die cut to request.

- Range of 5 thicknesses to suit most applications.

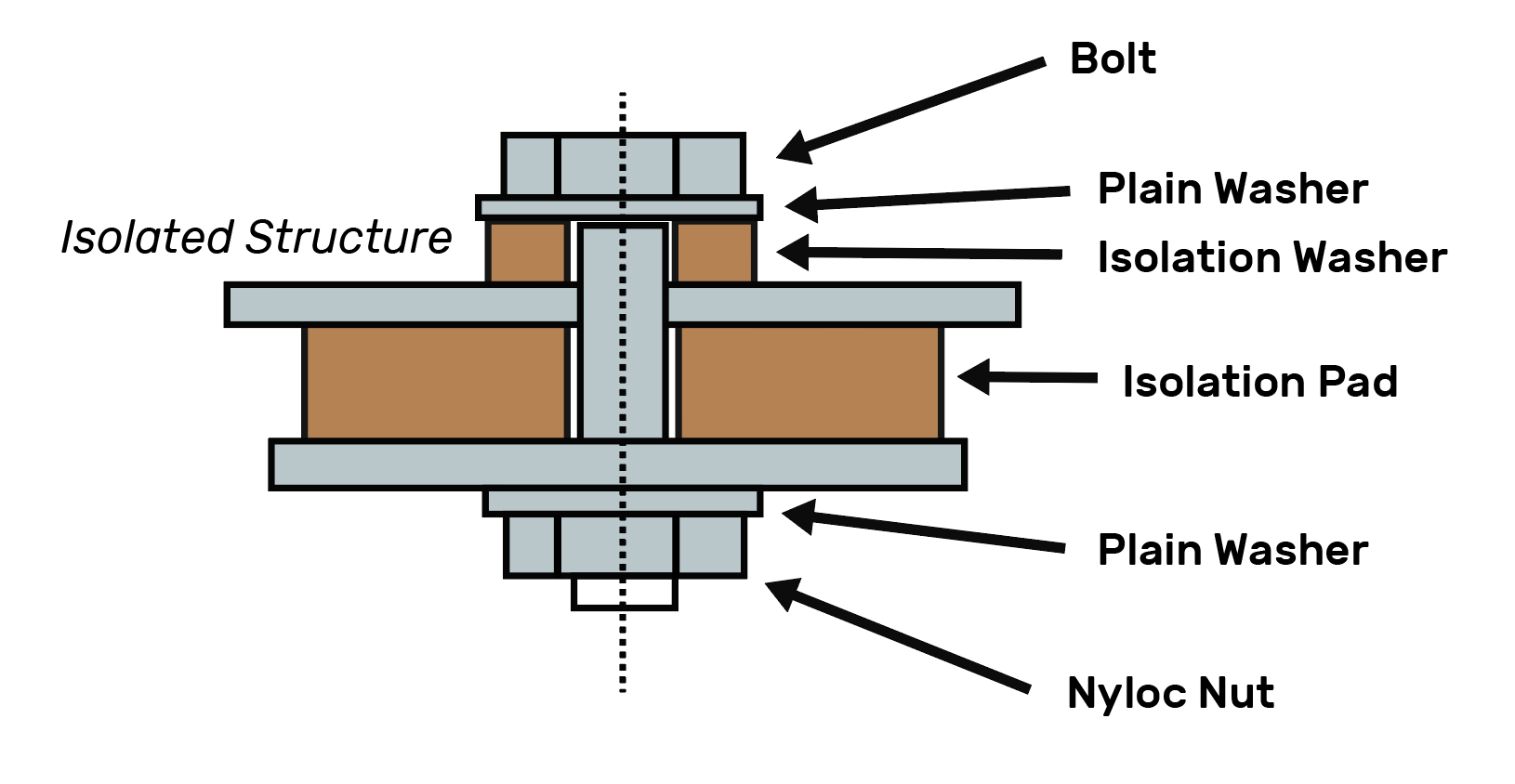

- Can be supplied in washers for effective isolation installation. See Diagram.

- Compressive strength 5.0kg/cms2 (0.50N/mm2)

- High resistance to common oils and solvents.

- Readily bonds into multiple layers for a range of thickness’.

- Prolongs the life of machinery.

- Retains its properties for good service life.

Some practical aspects and considerations when using Armadillo Armacork Antivibration Cork

- Compatible for a wide range of machine types.

- In most captive installations rebound washers will be required. (see diagram)

- Can be used with contact adhesive to avoid the need for anchor bolts.

Pad Area Selection Example

On most machine tools the contact area of the machine foot has been designed to limit the amount of stress the machine exerts onto the support foundation. For this reason it is most common to simply cut the Armacork pad to suit the area of the support foot. For confirmation of this the following calculation can be carried out.

- Take the total machine weight including maximum weight work piece in Kg’s.

- Measure the sizes of each mounting foot and work out the area in square centimetres.

- Add the total area of all the mounting points together to give the total floor contact area.

- Dividing the total machine mass by the total number of square centimetres gives the working stress the pads will be under on installation. This will be a number of kg’s per square centimetres. Armacork is designed to work at any working stress up to a maximum of 5 Kg/cms (0.50N/mm2).

Beyond this additional spreader plates will be required to reduce the working stress. Contact Armadillo for recommendation.

Technical Specifications in detail

Working Temperature.

Continuous temperature exposure limits for long life are 120°C maximum and -30°C minimum.

Armadillo Armacork Tolerances:

Pad Length/Width (mm) 1.6

Pad Thickness (avg.) 0.5